MARKETS

Medical Devices

& Life Sciences

At Velosity, care and precision are at the heart of our approach to contract medical device manufacturing. The Velosity team treats every component we design, manufacture, and ship as if it were made for a family member. We take pride in our meticulous process, taking every step to ensure you provide the patient with the utmost dedication and care.

Velosity develops innovative solutions that allow your patients to return to an active life as soon as possible. Early involvement, at the start of the design for manufacturing stage, enables us to provide a fully integrated solution that addresses your challenges from end to end – from design through manufacturing.

Velosity produces an extensive line-up of finished devices, assemblies, and complex components for numerous Fortune 500 medical companies.

WHAT WE OFFER

- Cutting-edge medical parts manufacturing that enhances speed and value, engineering efficient processes

- Design and manufacture of components for life-sustaining applications for Class II and Class III medical devices

- Innovative design and creative engineering

- On-time launches that meet all customer requirements and expectations

SOLUTIONS

Our Medical Device Manufacturing Services

Click below to learn more about our services, or scroll down to uncover our capabilities in the medical technology and device manufacturing markets.

Contract Manufacturing

Injection Molding

Precision Machining

Tool Design & Manufacture

Design Support & Engineering

Tool Sampling & Process Development

Program Transfer

Technology Transfer

Quality Assurance

MEDICAL DEVICES & LIFE SCIENCES

Injection Molding

For over 50 years, Velosity has earned the trust of some of the most discerning customers in the business today. We’ve earned the reputation of being “the” company that our customers trust with their most critical and demanding injection molding and contract manufacturing projects.

Insert molding, over-molding, two-shot molding, micro molding, or high-volume molding – at Velosity, we do it all. We have the manufacturing capabilities to process the complete range of engineering-grade and non-engineering-grade thermoplastic, elastomeric, and silicone materials. We combine experienced design, tooling, and engineering teams with highly advanced technology to help you successfully bring your products to market on time and within budget.

Our programs are scalable to meet any need. Whether it’s medium-volume production or a high-volume order involving millions of parts, Velosity produces best-in-class results.

MEDICAL DEVICES & LIFE SCIENCES

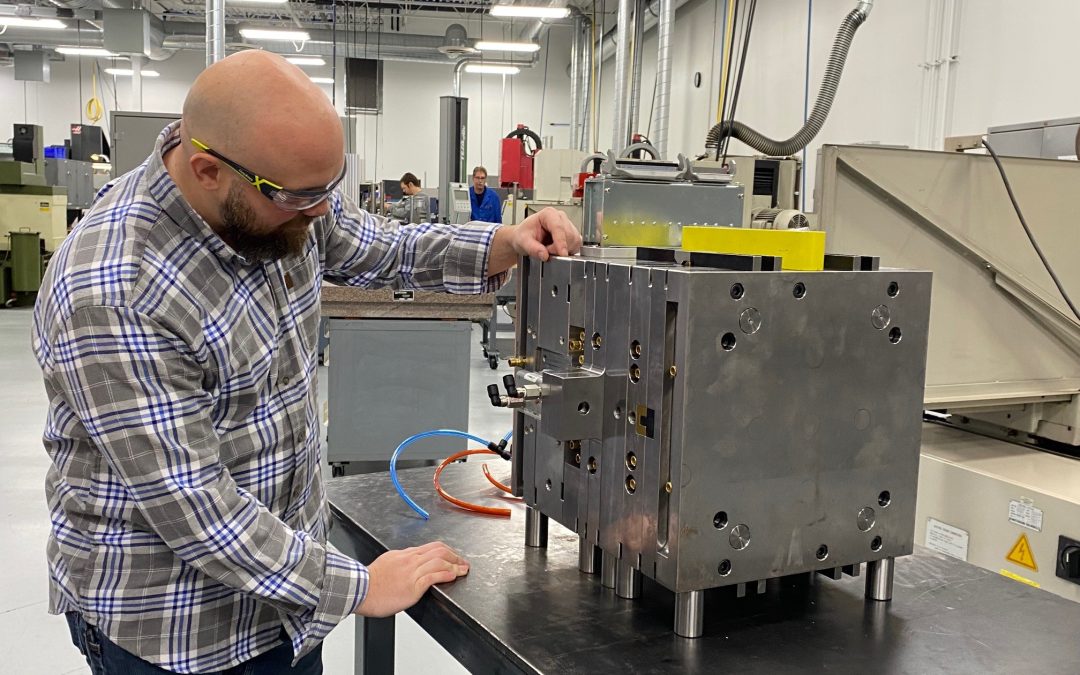

Tool Design &

Manufacture

With over 50 years of experience in tool design and manufacturing, our attention to detail ensures that you receive a tool that produces on-spec parts throughout the mold’s life. We take the time to design and engineer every mold to the highest level of integrity and quality.

Precision injection molding success begins with high-quality production tools. Velosity is one of the largest captive tool shops in the United States. With tooling and injection molding under one roof, our tooling designers work hand in hand to ensure your tool meets all aspects of your project requirements.

MEDICAL DEVICES & LIFE SCIENCES

Capabilities

Velosity specializes in integrating plastic molded parts and other manufactured components into a final, ready-for-use package. We have the knowledge and resources to develop, manufacture, and assemble everything from essential components to finished devices.

- Molding machines equipped with a robot or picker

- Clamp tonnages of 20 – 715 tons and shot sizes from 0.07 to 107 ounces

- Two-shot molding

- Thermoplastic, elastomeric, and liquid silicone (LSR) molding

- Micro-molding

- Numerous molding, assembly, and contract manufacturing clean rooms – ISO Class 8 & 7

- Large-format molding

- Precision machining of metals, plastics, and ceramics

- In-house tool design and manufacture

Professional Associations

Velosity maintains several professional associations, including Manufacturers Association for Plastics Processors (MAPP), The National Armaments Consortium (NAC), Defense Alliance, Manufacturers Alliance, and Minnesota Precision Manufacturing Association (MPMA).

RESOURCES

Meet Your Innovation Partner

Find more information about Velosity in our Case Studies, White Papers, and Brochures, or stay up-to-date by following our News & Events section.

Media Kit

PDFs

Videos

2025 Voice of the Team Engagement Survey

At Velosity, our people remain the heart of everything we do, and their voices continue to shape our growth and innovation. We’re excited to share the highlights from our 2025 Voice of the Team Engagement Survey! This initiative recognizes outstanding leaders across...

Tooling Brochure

For unparalleled quality, performance, and design, trust Velosity – the industry leader in designing and building...

PEEK and Titanium Spinal Spacer System

Solution Profile Velosity was challenged by a long-time customer to design, develop and qualify a complete manufacturing process for a thoracic spinal implant system that incorporates the molding of two additive manufactured titanium plates and consists of 75 size...

Program Transfer: A Proven Process

Executive Summary This white paper explores the best practices for a successful program transfer process. [hubspot_form text="Download Velosity Program Transfer White Paper"...